Control and Optimization for Advanced Manufacturing and Processing

Italy - Republic of Serbia

Overview

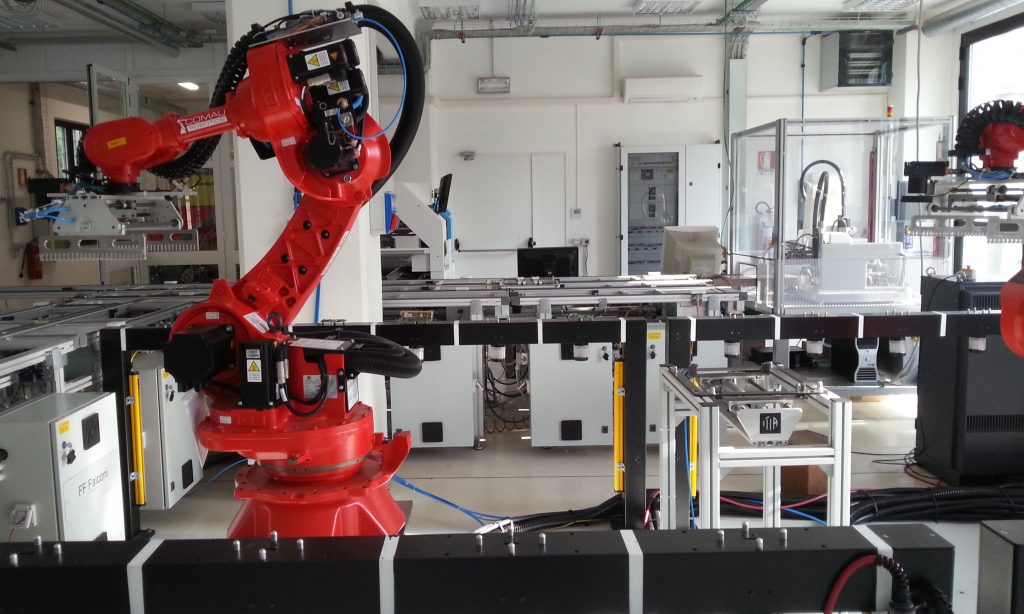

The goal of the COAMP-IRS project is to develop and test advanced techniques to optimally manage and control manufacturing plants, under the industry 4.0 paradigm.

This represents an opportunity to gain competitiveness in manufacturing industries, where ubiquitous communication, sensing, and computation enable the next generation of smart factories.

This is a strategic research field for both Italy and Serbia, give the large share contributed by manufacturing industries to both countries’ GDP, the strong existing synergies, and the prevalence of small and medium enterprises that need innovation to remain competitive in global markets.

Our 4 main objectives

Advanced control systems are also relatively cheap to install in existing plants to improve performance, since they require installing only interfaces (communications, software) and computational nodes, without changing the most expansive parts of the machines.

Morevoer, the use of real-time optimization is currently very limited in the manufacturing field, where heurestic rules are used. The potential for performance improvements is therefore extremely large.

Results

HPRC: a new approach to real-time routing in discrete manufacturing

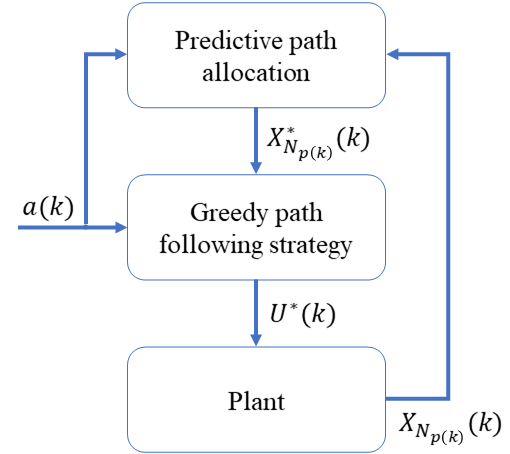

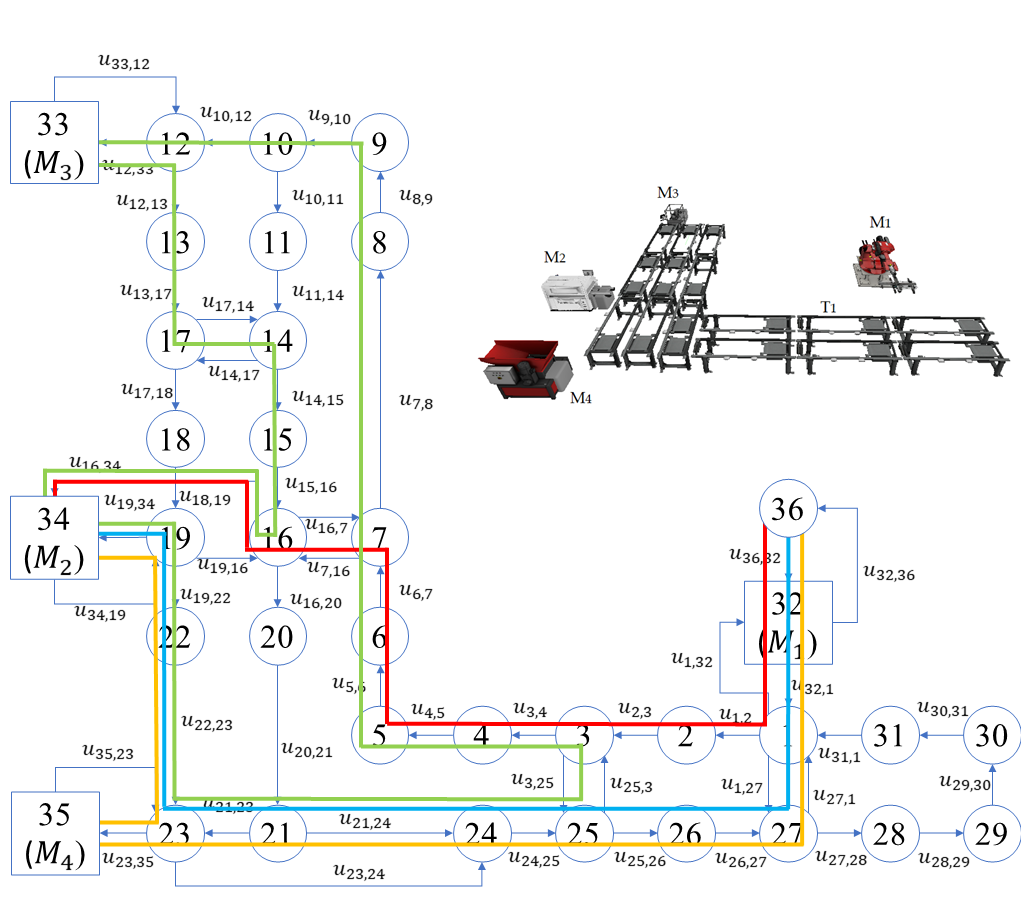

We developed a new paradigm, named Hierarchical Predictive Routing Control (HPRC), to address the problem of optimal routing of parts in a discrete manufacturing plants. HPRC delivers nearly optimal behavior with reduced computational effort, dealing with a large number of integer decision variables and temporal-logic constraints.

For details: paper; presentation; talk

Improved HPRC algorithm and high-fidelity simulation tests

We improved the HPRC optimization routine by introducing a search algorithm over the decision tree that exploit early detection of lockouts and the possibility to choose between a more cautious and a more aggressive routing strategy. We then successfully applied the approach to a high-fidelity model of the CNR de-manufacturing plant

For details: paper

Partners

Departament of Electronic, Information adn Bioengineering

Stiima – Inteligent Industrila Systems and Technologies for Advanced Manufacturing

Funding

and internation Cooperation (MAECI)

Contact us

For more information about this project, send us an email at coampirs-deib@polimi.it

Italy – Republic of Serbia

+39 02 2399 3400

Via Ponzio 34/5, 20133 Milano, Italia

Funding

Politecnico di Milano, Via Ponzio 34/5, 20133 Milano, Italia